Detail Engineering

Our detail engineering covers all relevant engineering disciplines and planning steps up to the commissioning of the process plant - if required also as part of an EPCM project team.

What exactly does detail engineering involve?

The time required to complete a project is largely attributable to detail engineering. In this phase, all the necessary documents for assembly and commissioning are prepared and subjected to close inspection. It is essential in project management to tie up the corresponding time and personnel resources to guarantee high quality requirements.

The results of this engineering phase are handed over to the procurement process in the form of tender and inquiry documents, including specifications for all the technical equipment and materials required for the erection of the process plant, including the erection services.

What our detail engineering includes?

- Final determination of the basic engineering

- On-site surveys if required

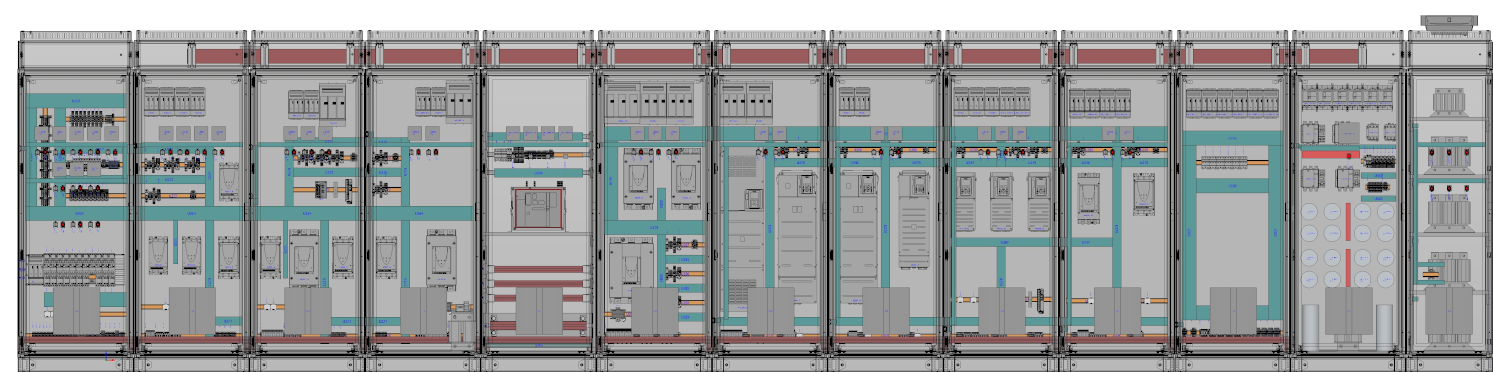

- Specification and design of EI&C equipment and control systems

- Preparation of technical specifications

- EI&C technology

- Installation planning EI&C technology

- Documentation

- Preparation of specifications for installation and commissioning

- Preparation of tender documents based on data and specifications from end customer

- Field device communication via field bus (Profibus/Profinet), service bus and remote I/O incl. fiber optic cable

- Technical coordination & clarification with suppliers / assembly companies

- Assembly supervision and support during commissioning

- Confident handling and relevant knowledge of valid technical standards and regulations

- Updating of inventory plans and their continuous maintenance

- Change management

- Configuration management